-

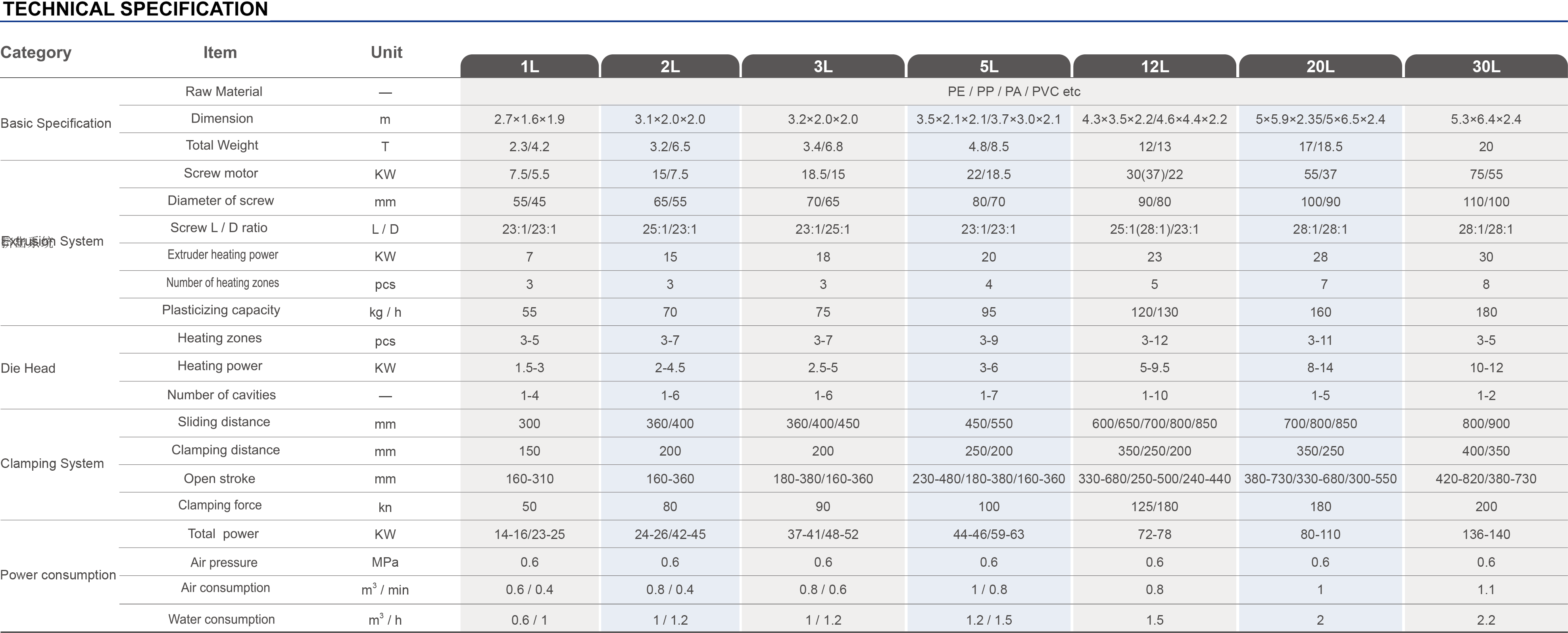

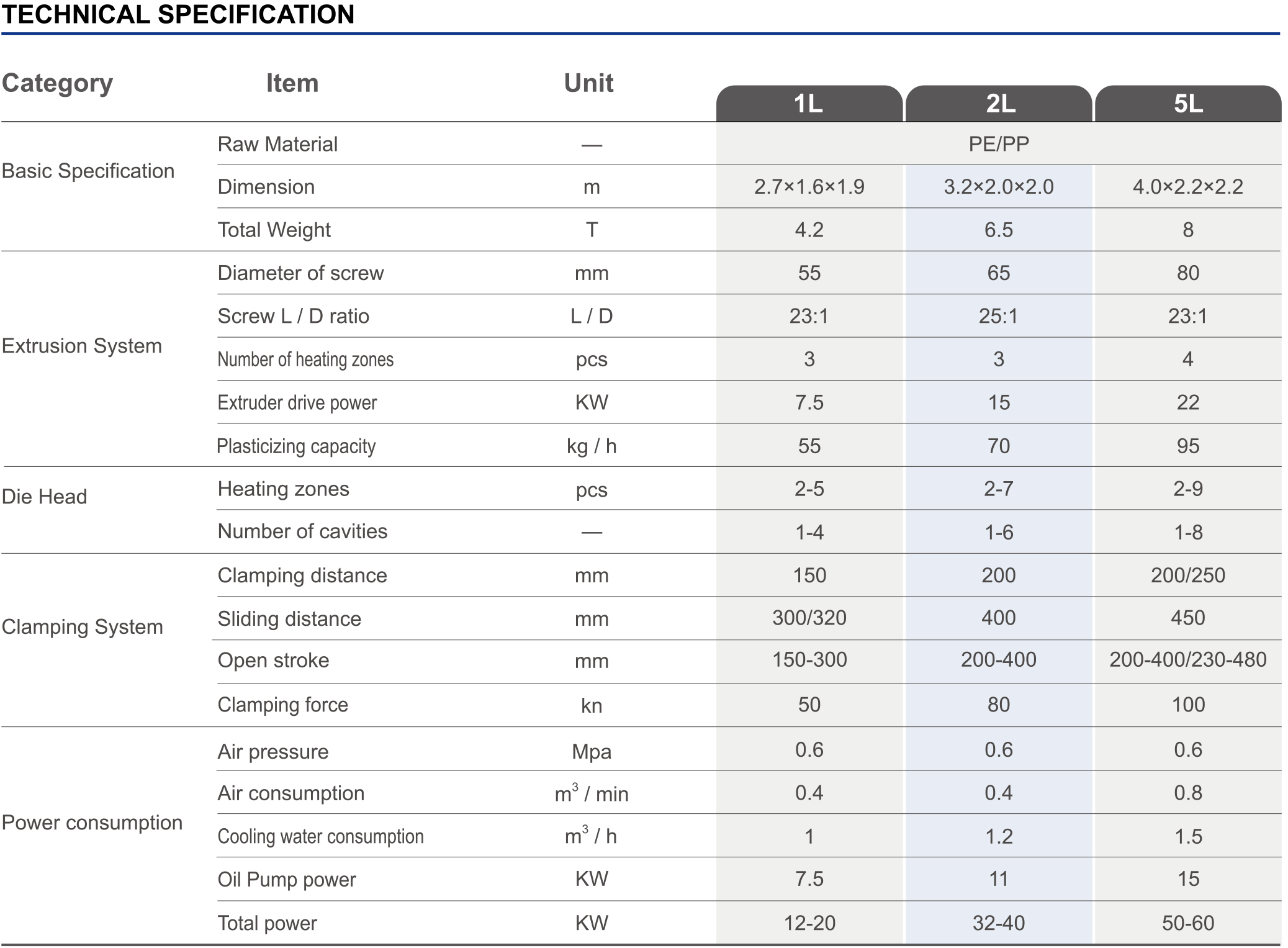

EXTRUSION BLOW MOLDING MACHINE

1L 2L 3L 5L 12L 20L 30L

Technical Characteristic

1.As our standard series, it performs well and years of development and improvement has won wide acknowledge from our clients. Annual global sales have reached hundreds of sets.

2.Plastic products from 1ml to 30L are suitable to be made on this machine, like medicine bottle, toy, cosmetic bottle, juice bottle, tool packaging, jerry can and so on.

3.Number of layers: 1 layer to 6 layers.

4.According to different needs can be equipped with conveyor, labeling machine, manipulator, Bottle leak detector, packing machine and so on.

-

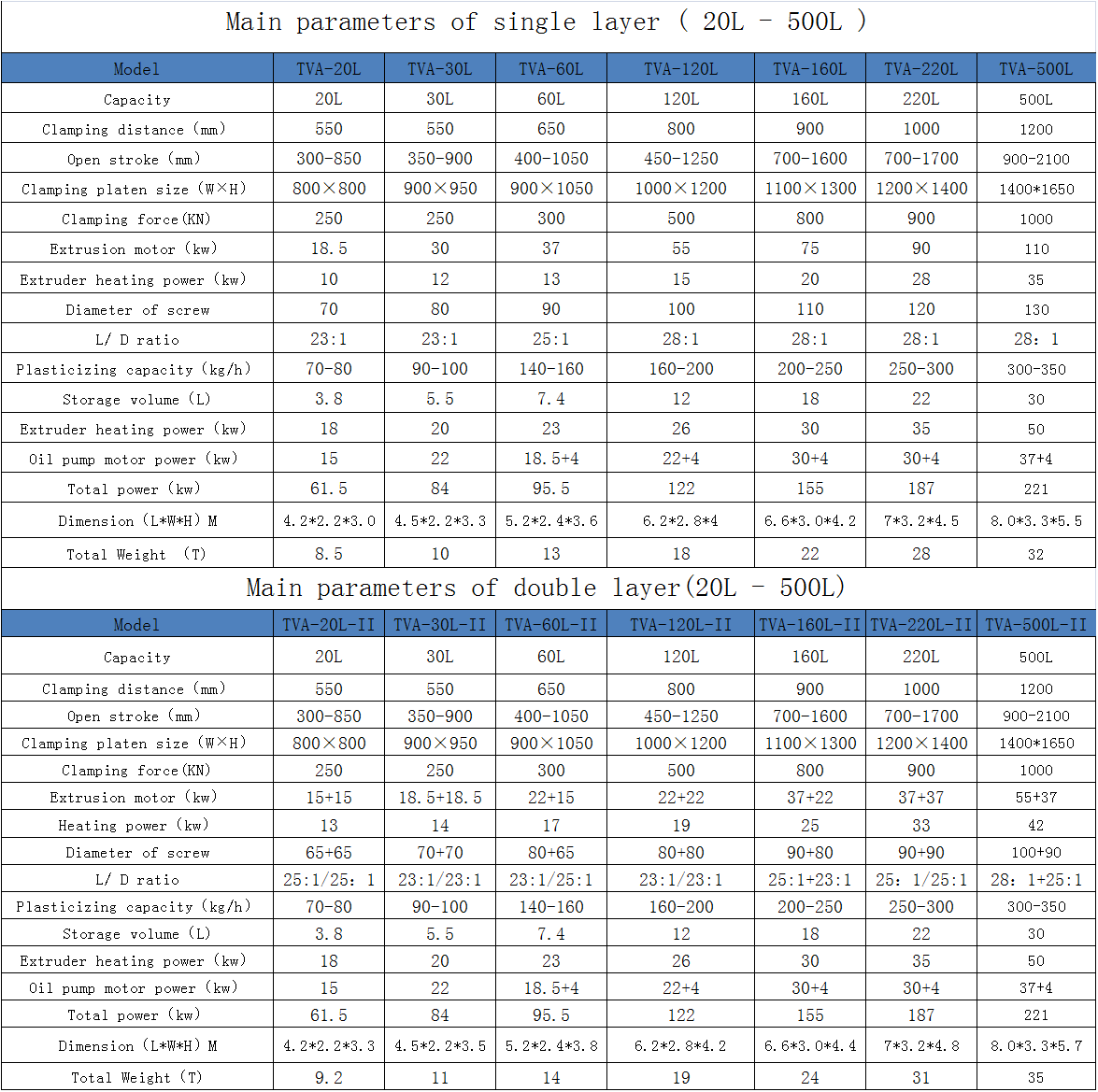

BLOW MOLDING MACHINE TVA 20L-500L

20L 30L 60L 120L 160L 220L 500L

Technical Characteristic

1.“A” Series is well applied to produce various kinds of blow molded products, such as chemical drum, toolbox kids play toy, chair, auto parts and pallet.Machine can effortlessly stores material in a short time with the design of accumulator die head, and with imported hydraulic control system, it runs more reliably and steadily. We also adopt advanced parison controller system to precisely even the wall thickness of products.

2.Number of layers: 1 layer to 3 layers.

3.Clamping Structure: Three-plate and inclined arm double pull-rod work together with the clamping structure.Plates are big enough to hold large-sized mould and mould opening & closing operates stably. More importantly deformation is no way to appear.

-

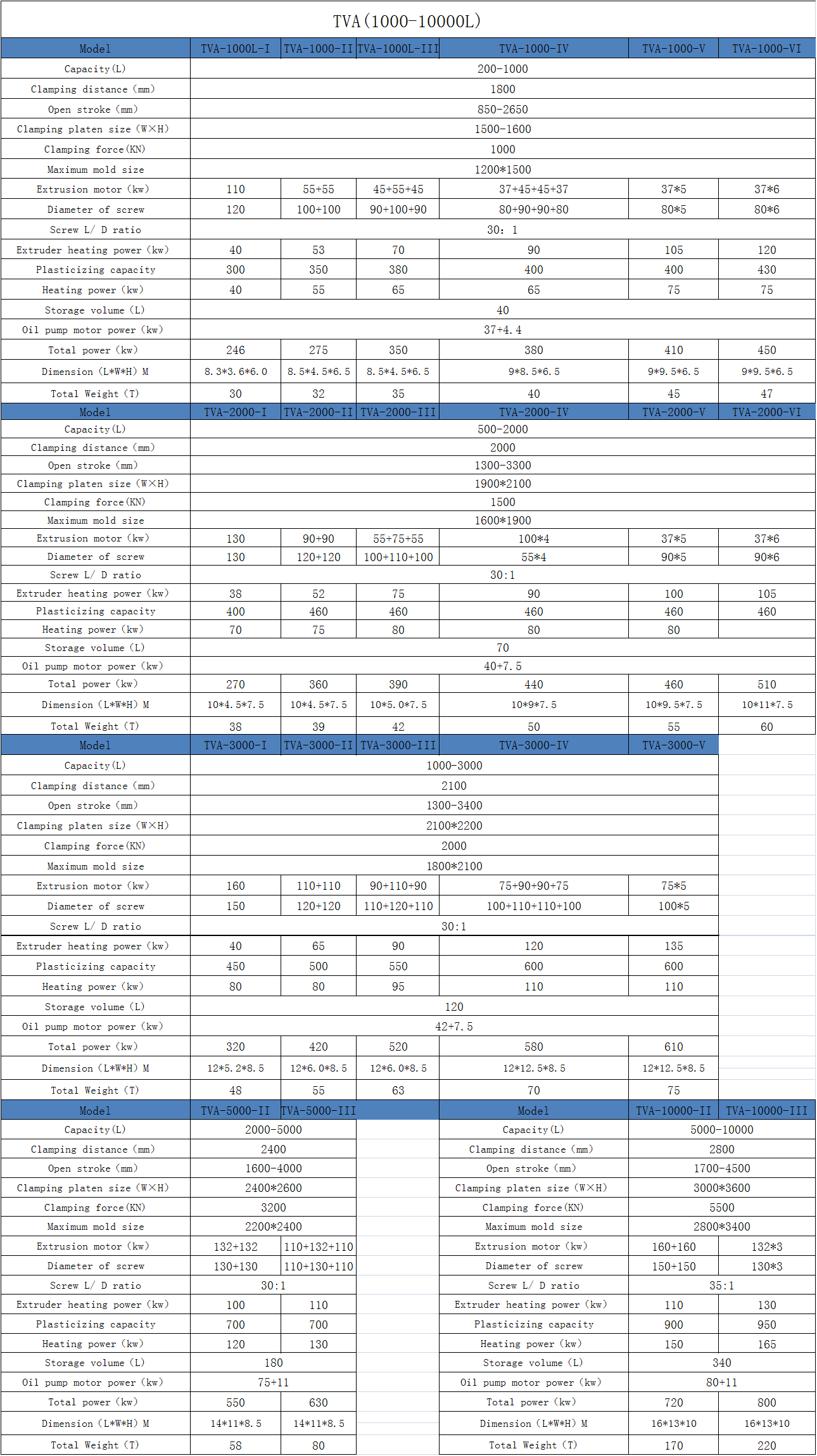

BLOW MOLDING MACHINE TVA 1000L- 10000L

1000L 2000L 3000L 5000L 10000L

Technical Characteristic

1.“A” Series is well applied to produce various kinds of blow molded products, such as chemical drum, toolbox kids play toy, chair, auto parts and pallet.Machine can effortlessly stores material in a short time with the design of accumulator die head, and with imported hydraulic control system, it runs more reliably and steadily. We also adopt advanced parison controller system to precisely even the wall thickness of products.

2.Number of layers: 1 layer to 3 layers.

3.Clamping Structure: Three-plate and inclined arm double pull-rod work together with the clamping structure.Plates are big enough to hold large-sized mould and mould opening & closing operates stably. More importantly deformation is no way to appear.

-

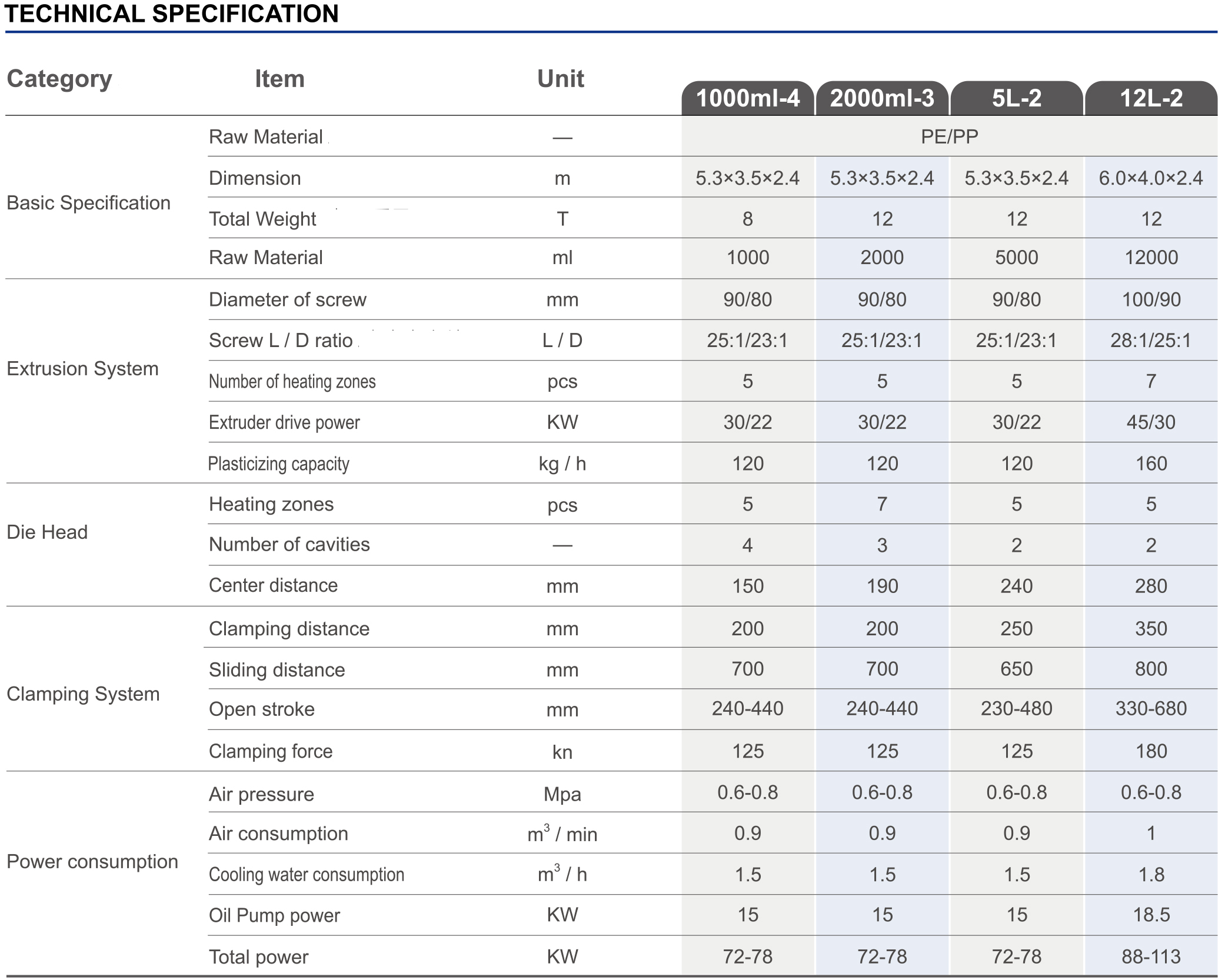

FUEL BOTTLE/CHEMICAL DRUM/CIVIL BARREL MACHINE

1000ML 2000ML 5L 12L

Technical Characteristic

1.It is suitable for producing 1L-12L fuel botle, lubricating oil bottle, etc.

2.Smooth treatment inside the die head with no dead angle in the curve fow runner gives good effect to smoothness and no lines outside and inside the finished products.

3.The effect of multi-layer co-extrusion, with the option of visible line design in the finished product, ensures uniform thickness in layers and the -shaped flow runner design inside die head, with less than two hours of color change, create translucen!and straight visible line with even width top and bottom.

4.Machine can be equipped with auto deflashing, take-out units for finished product, conveyors for waste material and finished product, in-mould label and leak tester.

5.This model can be upgraded into "Hybrid Type" , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

-

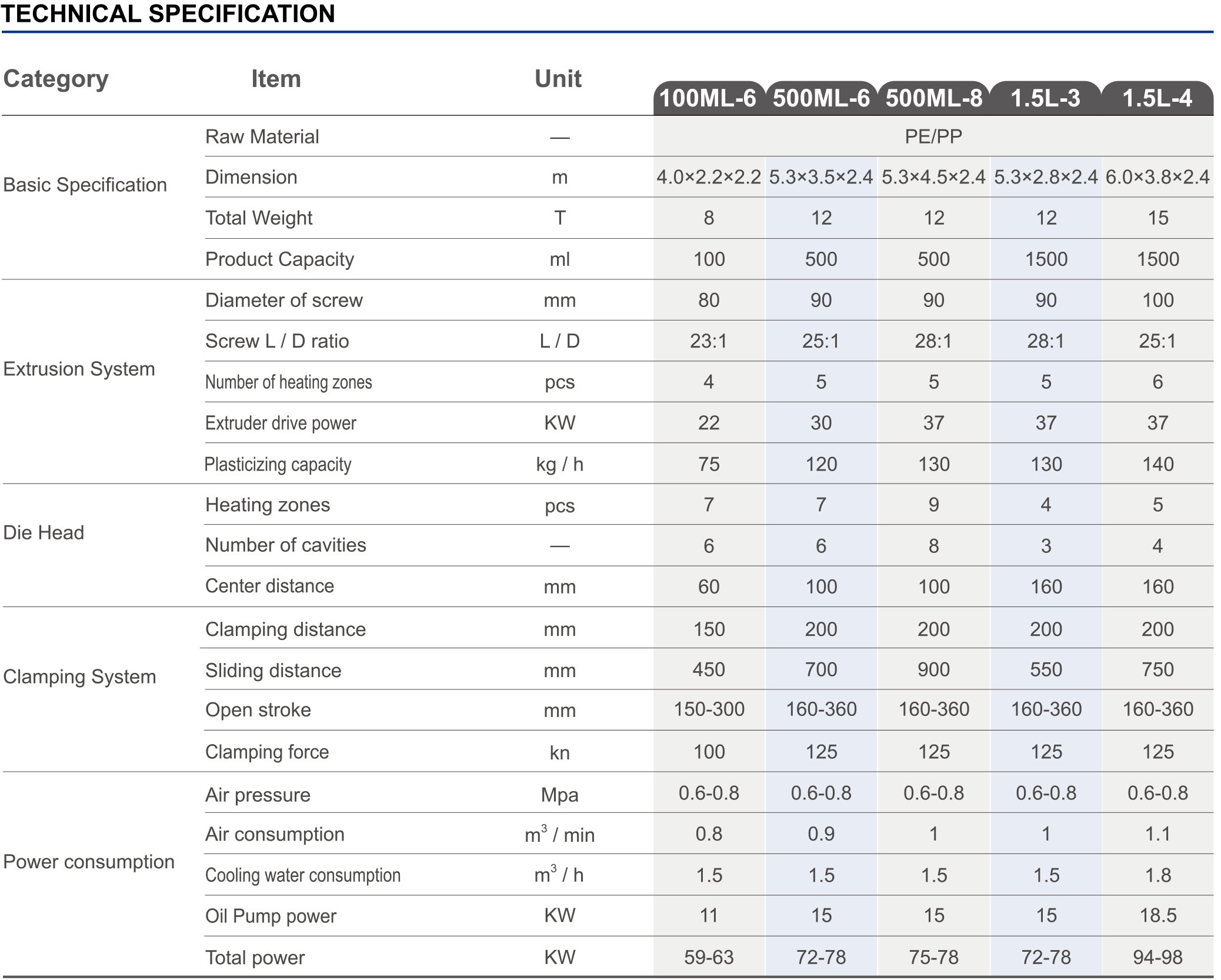

MILK BOTTLE MACHINE

100ML 500ML 1.5L

Technical Characteristic

1.This model is featured as follows: multi die head, double station and high production. Bottle wall thickness of each cavity is made even with the design of center feeding die head, processed by CNC machine center.

2.Machine uses imported brand for hydraulic components and adopts double proportional valve to control the flow speed and pressure of oil circuit which can also be managed online. Movement of the above is stable and smooth.

3.MOOG 100 Points Parison Controller System can be adopted to further improve product quality.

4.This model can be upgraded into "Hybrid Type" , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

5.Machine can be designed to work with robot arm, conveyor, leak tester, in-mould label, packaging machine, etc. as per your requirement.

-

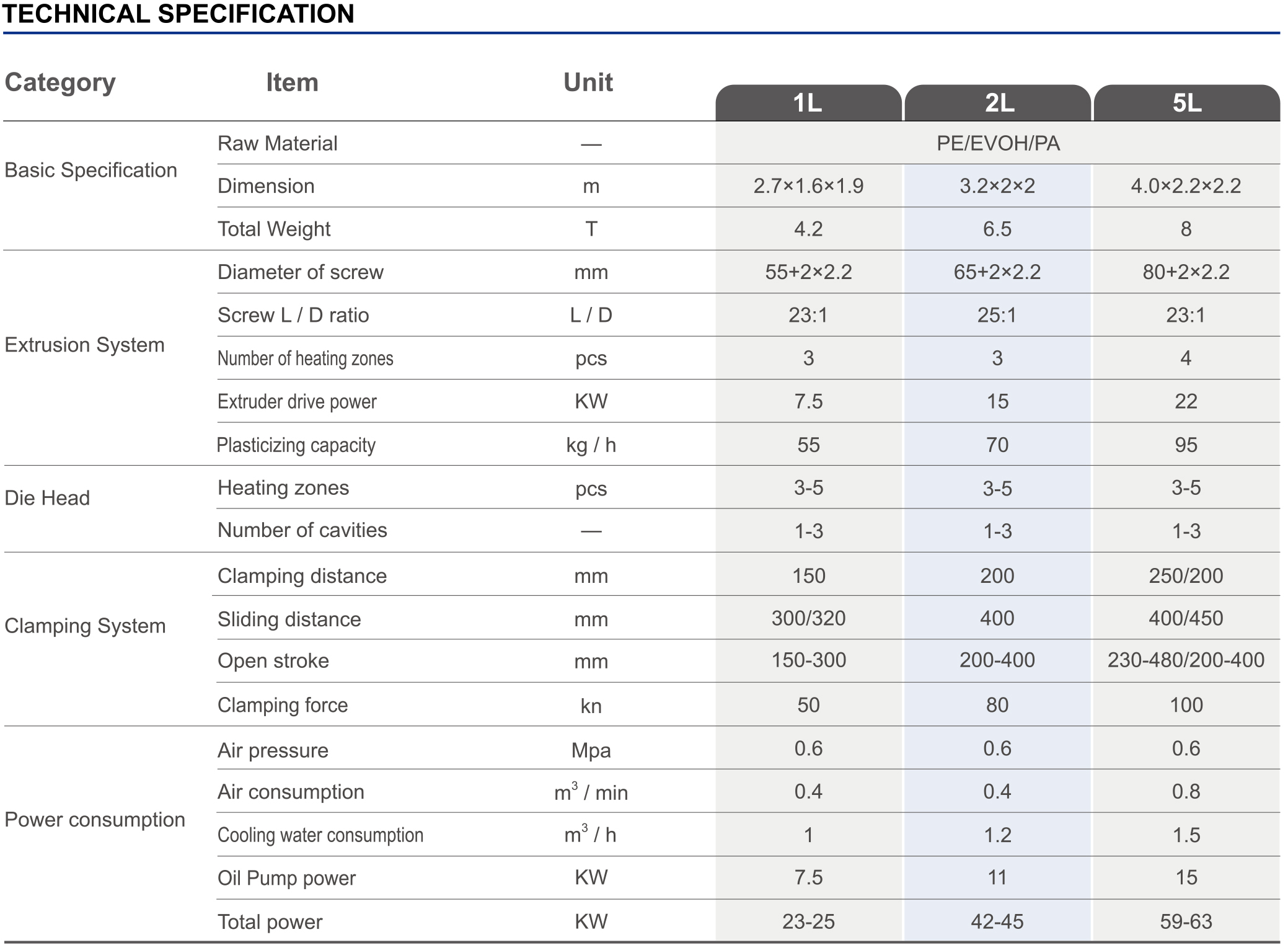

PESTICIDE BOTTLE MACHINE

1L 2L 5L

Technical Characteristic

1.Multi laver co-extrusion is optional and special shaped flow runner inside the die head gets uniform thickness of each layer and thickness of EVOH layer can be controlled within 0.03mm.

2.Toggle clamping structure without pull-rod design has even and strong clamping force and big mould-fixing plate.

3.Machine can be added with hydraulic servo system, visible line design, robot arm, conveyor, leak tester, packaging machine and so on.

4.This model can be upgraded into "Hybrid Type" , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

-

PHARMACEUTICAL PACKAGING PRODUCTS MACHINE

100ML 500ML 1.5L

Technical Characteristic

1.Toggle clamping structure without pull-rod design has even and strong clamping force and big mould-fixing plate.

2.Bottle wall thickness of each cavity is made even and outer surface is smooth with the design of center feeding die head, processed by CNC machine center.

3.Well-performed hydraulic components, in imported brands, ensure machine runs stablv and efficiently.

4.MOOG 100 Points Parison Controller System can be adopted to further improve product quality.

5.This model can be upgraded into "Hybrid Type" , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

6.Machine can be designed with robot amm, conveyor, leak tester, in-mould label, packaging machine, etc. as per your requirement.

-

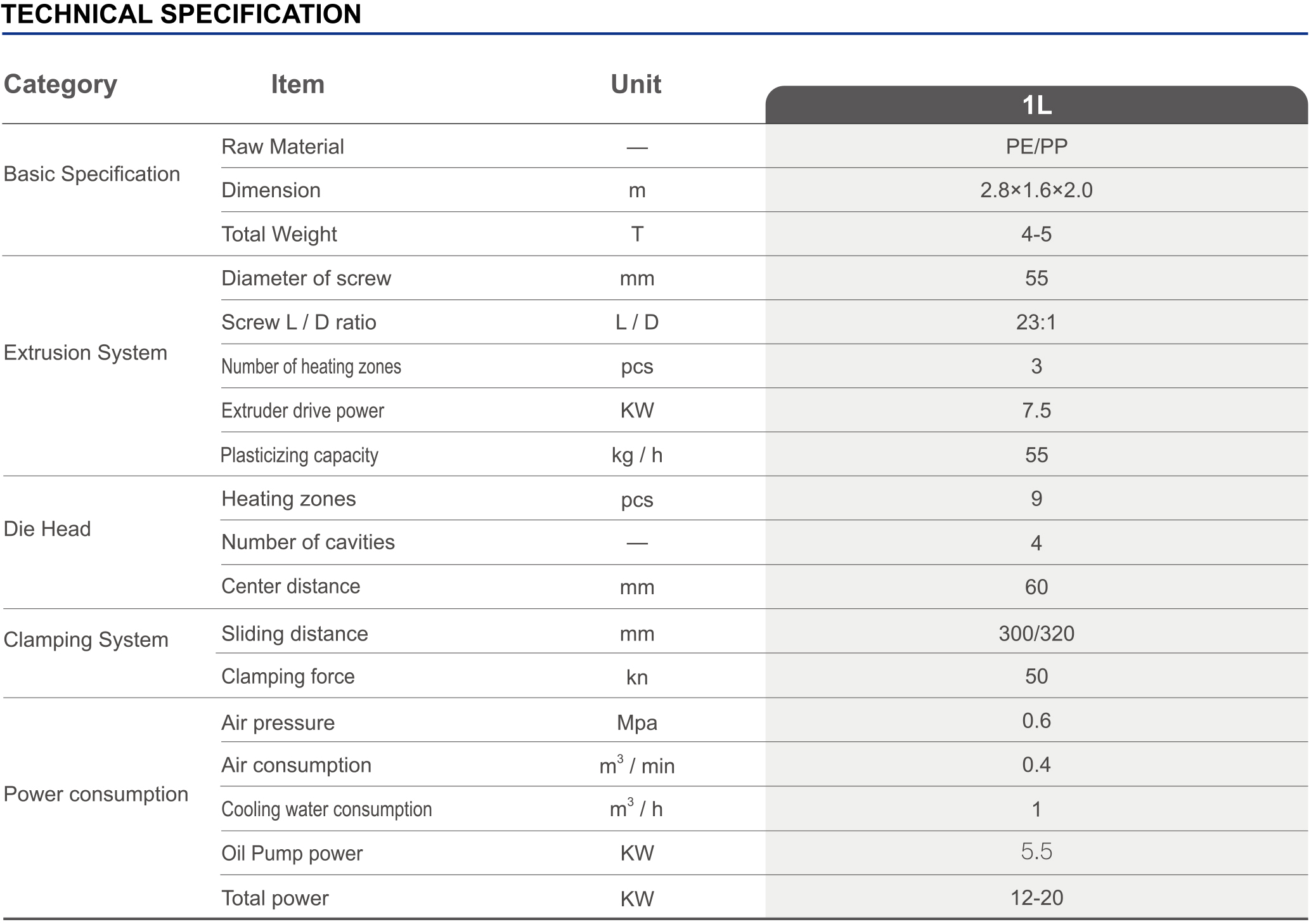

PASTEUR PIPETTER DROPPER / ENEMA MACHINE

1L

Technical Characteristic

1. This model is characterized by no pollution, high speed, stability, energy saving and precise position of carriage moving.

2. Machine is manufactured with no hydraulic system but servo motor-control system is adopted to swiftly accurate mould moving position with quick response of strong clamping force. Thus, no-pollution production environment greatly meets requirements of pharmaceutical packaging.

3. High-speed and stable production can amount to over ten thousand pcs per day. And 40% energy can be saved compared to hydraulic system.

4. Newly-designed interior structure of the die head well guarantees the melting plastic comes down straight with no deviation.

Weight error can be controlled to 0.1 gram.

5. Rate of failed products can be effectively lowered as it is simple and easy to learn about machine adjustment and operation.